X-BAG EVO

Vertical bagging machine - PLC and Touch Screen control - Suitable for different types of film

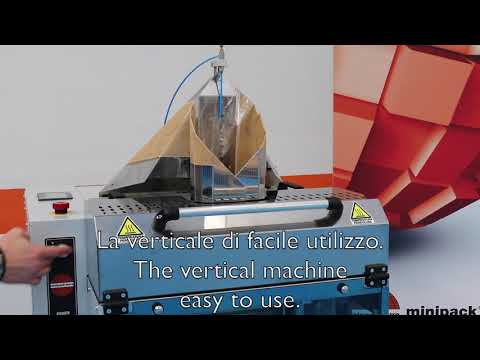

X-BAG EVO: THE LATEST GENERATION VERTICAL MACHINE

Simple to use. Simple to maintain. Simple to install.

X-BAG evo is the ideal solution for those who need to quickly bag small quantities of materials (fresh food, small parts, spare parts, instruction manuals, small industrial components,etc.), in hermetic packages, in different formats and with different types of films.

X-BAG evo makes packaging simple: that’s why it offers a genuine alternative to time-consuming manual packaging – and even to automated packaging with its larger and more complex machines, which are often inadequate for actual packaging requirements and come with higher operating and maintenance costs.

Practical and handy, the X-BAG evo can operate in continuous or pulse-based mode. It’s so compact it can be placed in any kind of environment, even in restricted spaces.

technical features

| Electrical Power Supply | V | 220/240 |

| MAX power installed | kW | 0.5 |

| Pneumatic supply | bar | 40l/m up to 6 bar |

| Hourly output | p/h (pph) | 0-1000 |

| MAX Reel Dimensions (diameter) | mm | 250 |

| MAX Reel Strip Dimensions (width) | mm | 360/410/520 |

| Film thickness | micron | 15/50 |

| Bag length | mm | 50/330 (mm 580 with belt) |

| Bag width | mm | 170/185/235 (depending on collar) |

| Type of film that can be used | type | Polyethylene, polyolefin, macro-perforated, coupled, biodegradable films, cartene plastic, printed films) |

| Horizontal sealing | type | Double mental strip and cutting line |

| Machine dimensions | mm | 800x850x1500 |

| Machine weight (Net/Gross) | kg | 130/165(MF99MB75) 135/170(MF99MB76) |

minipack®-torre shall not be held liable for typos or printing errors in this catalogue. It also reserves the right to make changes to the specified features without prior notice. All trademarks are property of their respective owners and are hereby acknowledged.

- CATALOGUE X-BAG837 KB

- Download pdf

Register it now on our website...

Would you like to pack your products with this machine? Book your free, non-binding packaging test.