3G UMTS stick

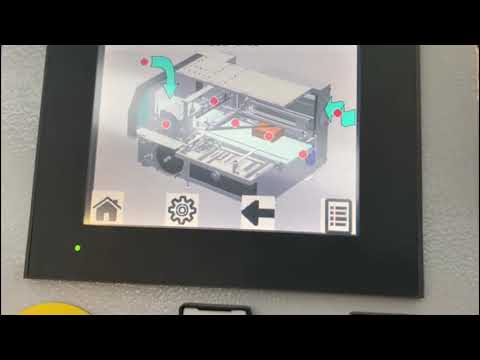

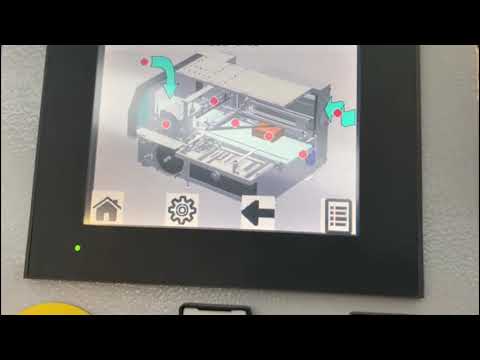

PRATIKA 80-T MPS

Automatic packaging machine - Continuous sealing (sealing bar 700mm x ∞ ) - Fully electrical and servo-assisted

Pratika 80-T MPS: the wrapping machine for continuous sealing

PRATIKA 80-T MPS: automatic wrapping machine. The acronym indicates the side seal device, the continuous welding that does not involve length limits to pack up to 4, 5, 6 meters. In addition to the equipment of the Center Sealing system, this new version of the machine, suitable to pack large sizes up to 700 mm wide x360 mm high, has been enhanced with a strong mechanical and electronic technological content.

Pratika 80-T MPS is an innovative shrink wrap machine that represents today a perfect synthesis of reliability, high performance, versatility and safety, to evolve once again the way to conceive automatic packaging machines with shrink films.

"Made in Italy with an international heart": all the automatic wrapping machines by minipack®-torre are produced entirely in the company's factories, with an inner heart made of the electrical and electronic components of a multinational corporation such as Schneider Electric.

PRATIKA 80-T MPS the most appreciated model of the new range of minipack®-torre automatic wrapping machines:

- Continuous welding system

- "Center Sealing" welding device

- Brushless servomotor by Schneider Electric

- Control logic by Schneider Electric PLC

- Electric power supply, no pneumatic connection needed

- Reduced energy consumption

- Compliance with CE regulations

technical features

| Electrical power supply | 230V 50/60Hz 1Ph |

| MAX power installed | 3 kW |

| Maximum current | 13 A |

| Available dimensions of the sealing bars | 700 mm x ∞ |

| MAX product size (the maximum measurements cannot be used at the same time) | 700x360 mm x L.∞ |

| MAX Reel Dimensions (Ø x length) | Ø350x1000 mm |

| Infeed belt height | 915 mm |

| Machine dimensions (guards open) | 2785x3090x2280 mm |

| Machine dimensions (guards closed) | 2785x2490x1770 mm |

| Type of power supply | Electrical power supply |

| Hourly output (based on the size of the product and the film used) | 0-3000 p/h |

| Machine weight (Net/Gross) | 1270/1500 kg (Pallets)1270/1700 kg (Wooden crate) |

minipack®-torre shall not be held liable for typos or printing errors in this catalogue. It also reserves the right to make changes to the specified features without prior notice. All trademarks are property of their respective owners and are hereby acknowledged.

Register it now on our website...

Would you like to pack your products with this machine? Book your free, non-binding packaging test.Barcode Reader

Box for remote support

Product safety photocell kit

Film end photocell kit

Photocell kit for printed film

19kVA Auto-transformer kit 415/460V 3Ph SEC. 230V 1Ph/400V 3Ph

Wireless push-button kit

Kit with 32-needle wheel

Photocell kit for non-transparent film

Pedal kit

Anti-static brush kit

“Reel end warning” photocell kit

Waste separator kit

Powermeter Kit

Roller conveyor kit 2 m with protection

Roller conveyor kit 1 m with protection

Electric perforating kit

Kit of guides for unstable products (h. min.=55mm)

3500VA 50/60Hz Auto-transformer kit 180-210V / 230V

Easy open kit

Kit of guides for unstable products (h. min.=80mm)

Kit of guides for unstable products (min.h.=105 mm) + rollers

Belt for liquids wiper brush kit

Remote assistance module kit (Industry 4.0)

Sealing/cutting kit